automated warehouse conveyor systems

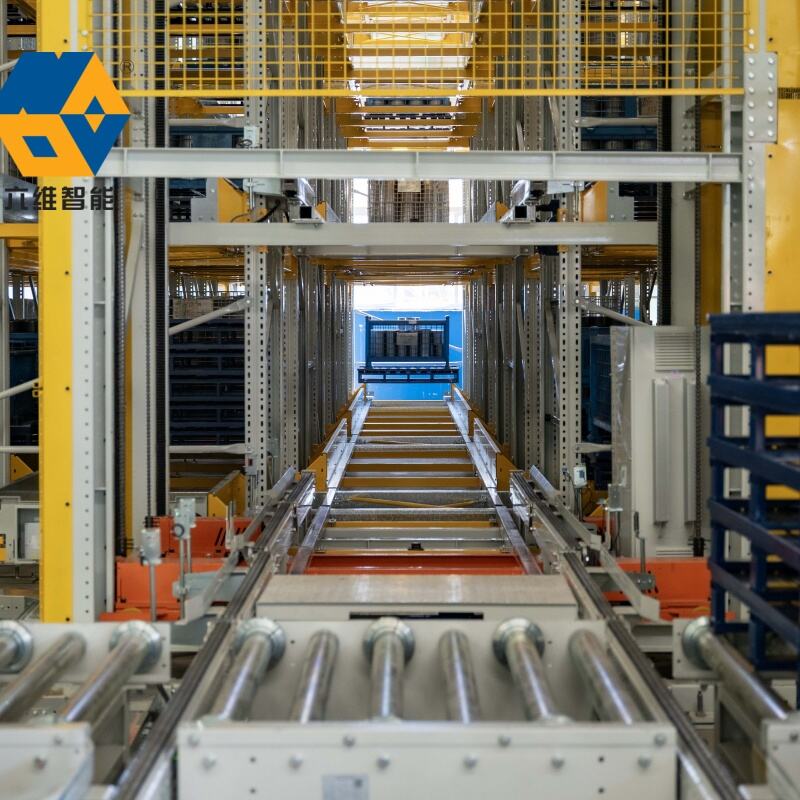

Automated warehouse conveyor systems represent a cornerstone of modern logistics and material handling operations, combining advanced automation technology with sophisticated mechanical engineering. These systems comprise interconnected networks of powered conveyors that efficiently transport packages, pallets, and products throughout warehouse facilities. The core functionality includes automated sorting, accumulation, merging, and distribution of materials across various warehouse zones. These systems utilize multiple conveyor types, including belt conveyors, roller conveyors, and chain conveyors, each optimized for specific product characteristics and operational requirements. Advanced sensors and control systems enable real-time tracking and routing of items, while integration with Warehouse Management Systems (WMS) ensures seamless coordination of material flow. Modern automated conveyor systems incorporate smart features such as automatic speed adjustment, load detection, and predictive maintenance capabilities. They can handle various product sizes and weights, operating continuously in multiple shifts while maintaining consistent performance levels. The systems are modular in design, allowing for future expansion and reconfiguration as business needs evolve. Safety features include emergency stop systems, guard rails, and automated shutdown protocols to protect both personnel and products. These systems significantly reduce manual handling requirements, increase throughput capacity, and improve operational accuracy in warehouse environments.