Introduction to ASRS Warehouses

Defining Automated Storage and Retrieval Systems

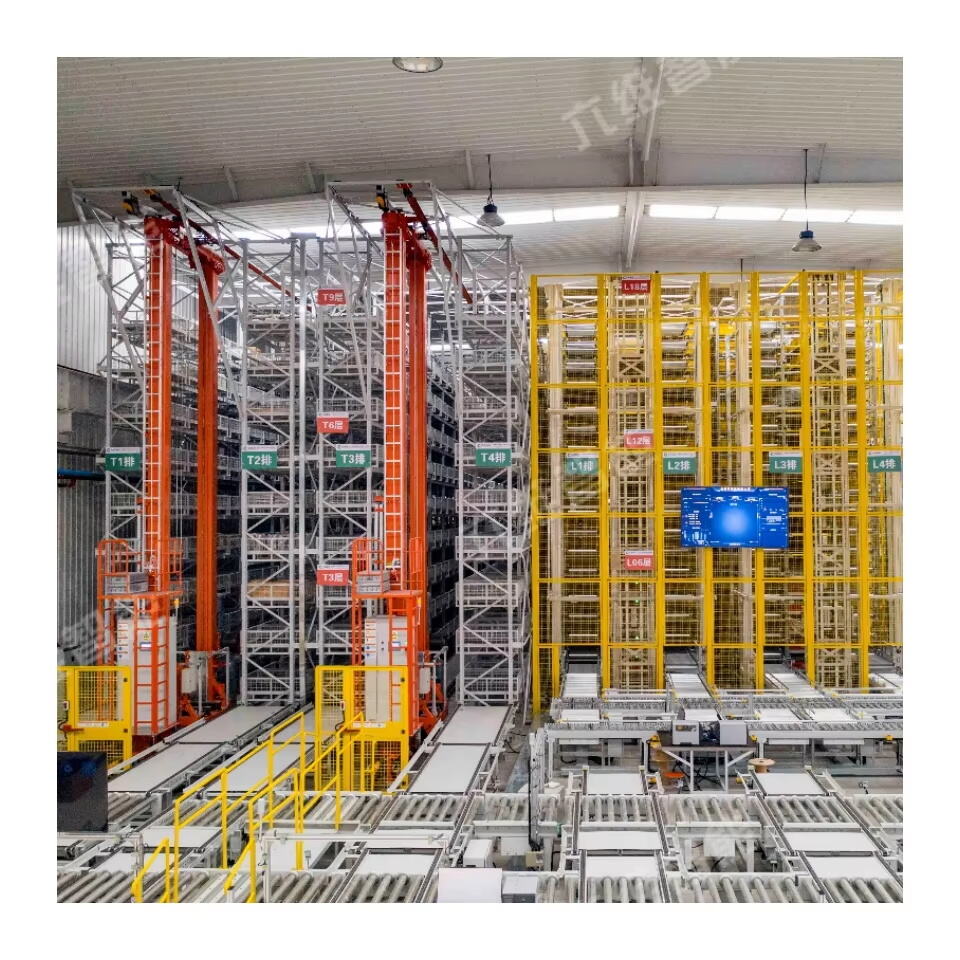

Automated Storage and Retrieval Systems (ASRS) are sophisticated solutions designed to enhance inventory management and streamline warehouse operations through advanced technology. These systems utilize robotics, software, and conveyor systems to expedite storage and retrieval processes, thereby optimizing space and reducing labor costs. The key objective of ASRS is to boost productivity by minimizing manual intervention and maximizing efficiency within warehouses. Such systems are pivotal in achieving effective inventory management, heralding a new era of warehouse automation defined by precision and speed.

The Evolution of Warehouse Automation

Warehouse automation has undergone significant transformation, originating from the industrial revolution as manual operations evolved into mechanized processes, leading to today's advanced automation systems. Technologies like RFID, IoT, and AI play a critical role in the evolution of ASRS, enhancing system functionalities and efficiency. This evolution is accompanied by market trends predicting a robust investment trajectory with ASRS system technologies expected to grow at a compound annual growth rate (CAGR) of approximately 12% in the coming years. The shift towards automation reflects the industrial demand for quicker and more precise services in the warehouse and logistics sector.

Why Modern Logistics Demands ASRS Solutions

The modern logistics landscape, significantly influenced by the rise of e-commerce, necessitates faster and more reliable warehousing solutions to align with consumer expectations. ASRS systems provide enhanced efficiency and accuracy, critical in maintaining competitive edge and operational excellence in logistics. Moreover, businesses are increasingly challenged by scaling and adapting to fluctuating demands, emphasizing the need for agile and flexible warehouse operations. ASRS solutions cater to these demands, integrating seamlessly within logistics systems to ensure resilience and adaptability in response to dynamic market conditions.

How ASRS Technology Works

Key Components: Robots, Conveyors, and Software

ASRS technology relies on various components to function efficiently within a warehouse. Robots are crucial in ASRS, performing tasks such as picking, placing, and transporting goods, significantly enhancing productivity and precision. The incorporation of conveyor systems facilitates smooth and efficient movement of items, optimizing the operational workflow. Additionally, advanced software systems are essential for coordinating these components, integrating real-time data for effective inventory management and operational analysis, ensuring that the ASRS operates seamlessly.

Operational Flow: From Storage to Retrieval

The operational flow in ASRS begins when goods arrive at the warehouse, where they are scanned and identified. Subsequently, items are sorted and categorized, then stored in locations determined by ASRS algorithms to ensure optimal retrieval. When an order is placed, the retrieval process is automated; robots or automated vehicles promptly fetch items from their designated storage locations. This streamlined operation enhances efficiency, reduces errors, and speeds up order fulfillment, making ASRS indispensable in modern logistics.

Integration with Warehouse Management Systems (WMS)

ASRS systems integrate smoothly with Warehouse Management Systems (WMS), providing centralized control over warehouse operations. This integration is vital for maintaining inventory visibility, tracking product movements, and optimizing workflow. WMS software communicates with ASRS technology to adjust operations based on real-time data and analytics, ensuring that warehouses respond efficiently to changing demands and inventory levels, thus maximizing productivity and minimizing labor costs. Integrating these systems enhances warehouse efficiency and operational capabilities significantly.

Types of ASRS Systems

Unit-Load ASRS for Palletized Goods

Unit-load ASRS systems are designed to efficiently manage large items and pallets, making them ideal for warehouses dealing with bulk goods. These systems optimize storage capacity by utilizing vertical space, which enhances the overall flow of goods. Among the typical features are pallet shuttles and automatically operated cranes, both of which contribute to a more streamlined operation. This type of ASRS system is particularly beneficial for warehouses with high volumes of large inventory items, facilitating robust management and retrieval tasks essential for bulk materials.

Mini-Load Systems for Small Item Handling

Mini-load systems cater specifically to warehouses that handle high volumes of small items, thus improving the picking and storage processes. These systems utilize smaller shuttles and extraction devices, facilitating efficient retrieval and simplified storage strategies. Mini-load ASRS systems are especially advantageous in retail and distribution centers where numerous small SKU's exist. By streamlining operations tailored for smaller items, these systems ensure that picking accuracy and speed are enhanced, making them indispensable for environments with diverse and numerous small products.

Vertical Lift Modules (VLM) for Space Optimization

Vertical Lift Modules (VLMs) provide a compact solution for optimizing warehouse space by effectively utilizing vertical dimensions. Items are stored in trays that can move vertically, reducing the footprint of storage operations while enabling quick item retrieval. VLMs are particularly advantageous in environments where floor space is limited. These systems enhance space efficiency and provide significant storage density, making them suitable for operations looking to maximize capacity without extensive physical expansion.

Carousel-Based ASRS for Rapid Access

Carousel systems magnify the speed and efficiency of item retrieval by using an orbital rotation mechanism that quickly brings items to the operator. Known for their high-speed capabilities, these systems are particularly beneficial in environments requiring rapid access to frequently picked items. Carousel ASRS can accommodate a variety of item sizes, ensuring versatility for different inventory types. The adaptability of carousel systems makes them ideal for businesses looking to improve access and reduce retrieval times significantly, thereby enhancing overall operational productivity.

Benefits of Implementing ASRS

Maximizing Vertical Space Utilization

ASRS systems significantly boost warehouse storage capacity by leveraging vertical space. This allows warehouses to implement higher shelving solutions, efficiently accommodating more inventory. The effective utilization of vertical spaces can lead to substantial cost reductions in real estate and operational expenses. Companies can safely stack products vertically without compromising accessibility, thereby optimizing their storage solutions while maintaining safety standards.

Reducing Labor Costs and Human Error

The implementation of ASRS reduces reliance on manual labor, which leads to lower labor costs and minimizes human error. Studies have demonstrated that ASRS can enhance operational accuracy by up to 99%, significantly reducing mistakes during order fulfillment. By eliminating redundant manual processes, these systems allow staff to focus on higher-value tasks, improving overall productivity and workplace efficiency.

Enhancing Inventory Accuracy and Traceability

ASRS technology integrates sophisticated tracking systems that improve the accuracy of inventory counts and locations. This enhanced traceability allows for better stock management, ensuring timely replenishment and minimizing stockouts. Real-time data access through ASRS facilitates informed decision-making and boosts operational efficiency, paving the way for smoother and more reliable warehouse operations.

Scalability for Growing Business Needs

ASRS solutions are designed to seamlessly scale with business growth, providing warehouses the flexibility to adapt to increased inventory and order volumes. New components of ASRS can be integrated without necessitating a complete system overhaul, thus offering adaptability to evolving business demands. This scalability ensures that businesses are well-prepared to meet future requirements without incurring significant capital investments.

Industries Transformed by ASRS

E-Commerce and Omnichannel Fulfillment

The e-commerce sector demands rapid distribution and precise order fulfillment, a need effectively addressed by Automated Storage and Retrieval Systems (ASRS). These systems enhance speed and accuracy, crucial for accommodating high order volumes and consumer expectations. Omnichannel retail strategies benefit greatly from ASRS, as they improve inventory visibility across multiple sales channels, facilitating an integrated shopping experience. Case studies reveal that companies adopting ASRS within e-commerce have increased order processing speeds by up to 50%, demonstrating the significant impact of automation in streamlining operations.

Automotive Manufacturing and Parts Logistics

The automotive industry relies heavily on ASRS for efficient parts management, ensuring timely availability for assembly lines. These solutions minimize downtime through automated parts retrieval processes, enhancing overall production efficiency. Research supports that employing ASRS in automotive supply chains can cut lead times by up to 30%, underscoring its vital role in maintaining uninterrupted manufacturing schedules. The ability to manage inventory accurately and quickly retrieve components is indispensable in this fast-paced sector.

Pharmaceuticals: Precision in Cold Chain Storage

ASRS plays a critical role in the pharmaceutical industry, particularly for sensitive products requiring precise climate control. These systems ensure inventories remain within specified temperature ranges, complying with stringent regulatory standards. Moreover, the automation provided by ASRS significantly enhances accuracy in medication dispensing, vastly reducing the likelihood of errors. This capability is crucial for maintaining product integrity and safety, fulfilling compliance in cold chain storage solutions within the pharmaceutical sector.

Aviation and Heavy Machinery Components

In aviation, ASRS systems are pivotal for the safe and efficient storage of heavy machinery components. Specialized systems are tailored to meet the specific weight and dimension requirements of aviation materials, ensuring optimal handling. These solutions facilitate swift access necessary for maintenance and assembly, critical for sustaining operational uptime. ASRS provides the reliability and precision needed to manage substantial parts, thus supporting the industry's rigorous safety and efficiency standards.

For more information about ASRS Warehouse solutions and how they are revolutionizing various industries, you can explore detailed evidence in recent market studies.

FAQ

What are Automated Storage and Retrieval Systems (ASRS)?

ASRS are advanced systems that enhance inventory management and warehouse operations using robotics, software, and conveyors to expedite processes and optimize space.

How do ASRS systems integrate with existing warehouse operations?

ASRS systems integrate with Warehouse Management Systems (WMS) to maintain inventory visibility, track product movements, and optimize workflow based on real-time analytics.

What types of ASRS systems are available?

Types of ASRS systems include Unit-Load ASRS for large items, Mini-Load Systems for small items, Vertical Lift Modules for space optimization, and Carousel systems for rapid access.

What industries benefit from ASRS technology?

Industries such as e-commerce, automotive, pharmaceuticals, and aviation have been transformed by ASRS technology, each benefiting from enhanced efficiency and precision.

What are the key benefits of implementing ASRS?

Benefits include maximizing vertical space, reducing labor costs and errors, enhancing inventory accuracy, and scalability for growing business needs.