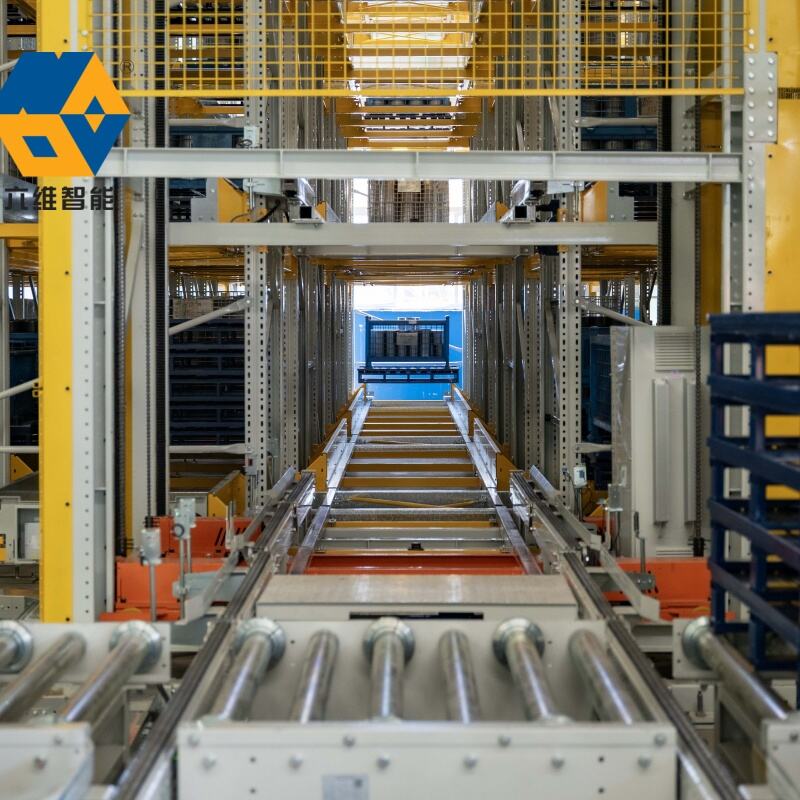

selective pallet racking system

Selective pallet racking systems represent the most widely used storage solution in modern warehousing operations. This versatile storage system consists of upright frames and horizontal beams that form a series of levels for storing palletized goods. The system's primary function is to provide direct access to every pallet position, making it ideal for warehouses handling diverse product ranges with varying turnover rates. Each storage position is independently accessible, allowing operators to retrieve any pallet without moving others, significantly improving picking efficiency and inventory management. The technological features include adjustable beam levels that can be modified in increments, heavy duty steel construction that ensures durability, and safety locking mechanisms that prevent accidental dislodgement of beams. The system can be configured to accommodate different pallet sizes and weights, making it adaptable to various storage requirements. Applications span across multiple industries, from retail distribution centers to manufacturing facilities, food and beverage storage, and e-commerce fulfillment centers. The system can be integrated with various handling equipment, including forklifts, reach trucks, and order pickers, enhancing operational flexibility. Modern selective pallet racking systems also incorporate advanced safety features such as load indicators, impact protection, and wire mesh decking for enhanced product security.