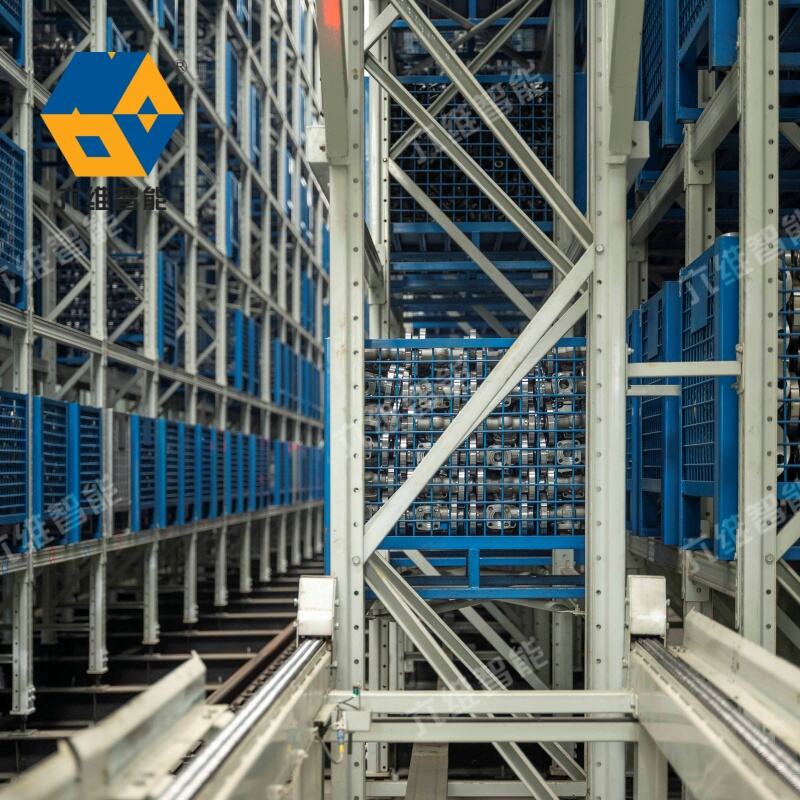

automated pallet storage and retrieval system

An automated pallet storage and retrieval system represents a cutting-edge solution in modern warehouse management, combining sophisticated robotics and intelligent software to revolutionize material handling operations. This advanced system utilizes computer-controlled machines, including automated cranes, conveyors, and shuttles, to efficiently store and retrieve palletized goods within a high-density storage environment. The system operates through a network of aisles fitted with storage racks, where robotic equipment moves both horizontally and vertically to access storage locations with precision. Integrated sensors and positioning systems ensure accurate placement and retrieval of pallets, while real-time inventory management software maintains detailed tracking of all stored items. The system can operate in various environmental conditions, including frozen environments, and can handle multiple pallet sizes and weights. Advanced safety features, including collision avoidance systems and emergency protocols, ensure reliable operation. The technology seamlessly integrates with existing warehouse management systems (WMS) and enterprise resource planning (ERP) software, providing real-time data access and inventory control. This system finds extensive applications in industries ranging from food and beverage to automotive and pharmaceutical sectors, where efficient space utilization and rapid inventory movement are critical.