automatic storage

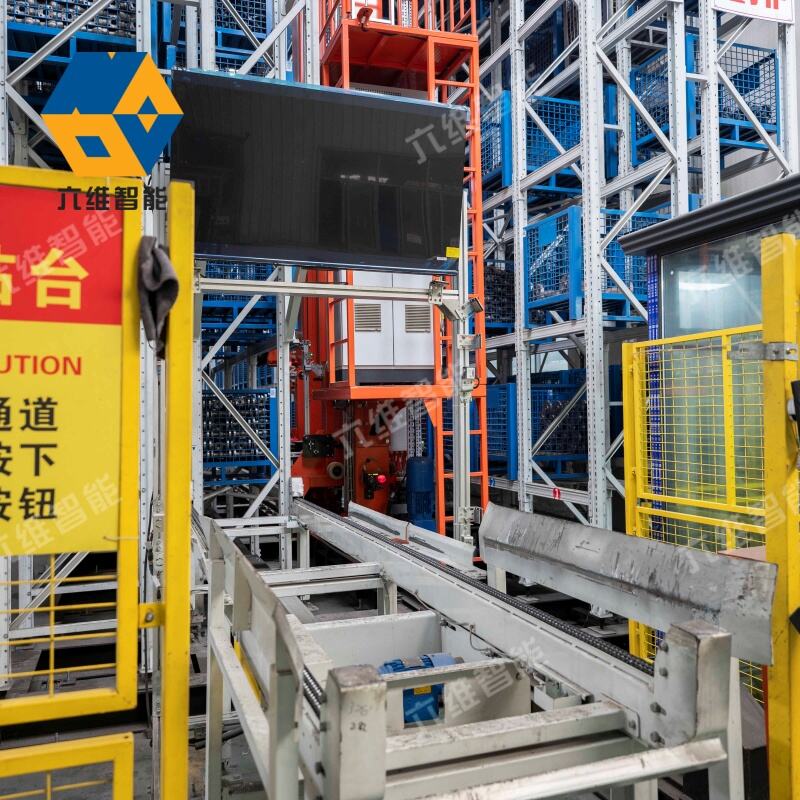

Automatic storage represents a revolutionary advancement in warehouse management and logistics, combining cutting-edge robotics, artificial intelligence, and sophisticated inventory management systems. This innovative solution transforms traditional storage facilities into highly efficient, automated environments where goods are stored, retrieved, and managed with minimal human intervention. The system employs a network of automated storage and retrieval systems (AS/RS), conveyor belts, robotic arms, and smart sensors to handle materials with unprecedented precision and speed. These systems can operate 24/7, maintaining consistent performance levels while significantly reducing human error. The technology integrates seamlessly with warehouse management software, providing real-time inventory tracking, predictive maintenance alerts, and optimization algorithms that maximize storage density and efficiency. Applications span across various industries, from e-commerce fulfillment centers to manufacturing facilities, pharmaceutical storage, and retail distribution centers. The system's ability to adapt to different storage requirements, handle various product sizes, and maintain specific environmental conditions makes it an invaluable solution for modern logistics operations.