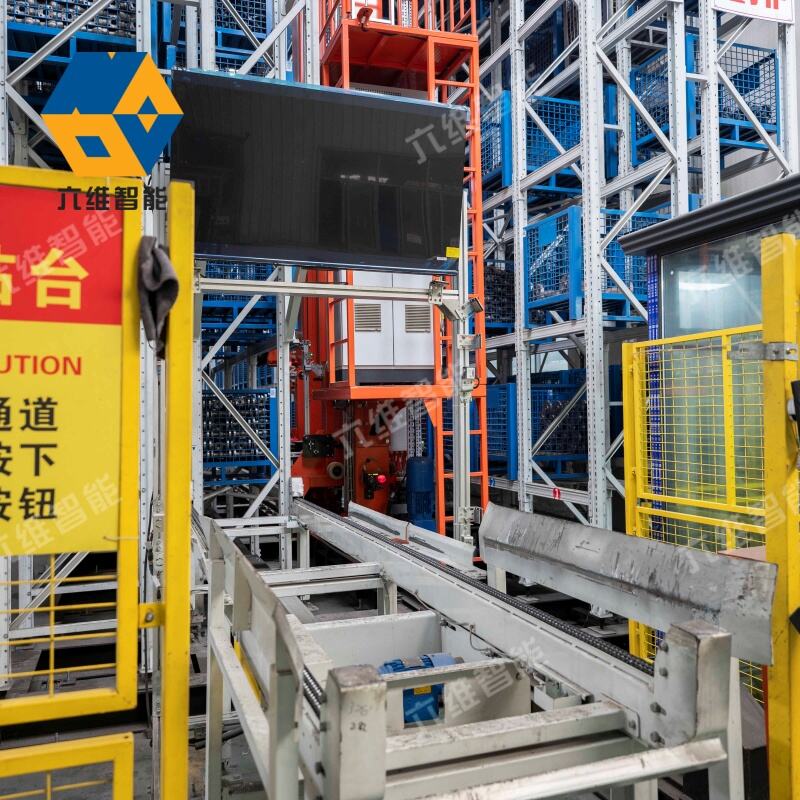

double deep pallet racking system

Double deep pallet racking represents an advanced warehousing solution that maximizes storage capacity by allowing pallets to be stored two deep on each side of an aisle. This innovative system effectively doubles the storage density compared to traditional single-deep racking, making it an ideal choice for facilities seeking to optimize their storage space. The system consists of specially designed uprights and beams that accommodate two pallets in depth, accessed by specialized reach trucks equipped with telescopic forks. The racking structure incorporates robust safety features, including heavy-duty frames, reinforced connectors, and protective elements to prevent damage during loading and unloading operations. What sets double deep pallet racking apart is its ability to maintain organized inventory management while significantly reducing the number of aisles required, leading to better space utilization. The system is particularly effective for storing large quantities of similar products or items with moderate turnover rates. Modern implementations often include advanced warehouse management systems that track pallet positions and optimize picking sequences, ensuring efficient operation despite the deeper storage configuration. This racking solution proves especially valuable in cold storage facilities, distribution centers, and manufacturing warehouses where space optimization is crucial for operational efficiency.