warehouse shelving systems

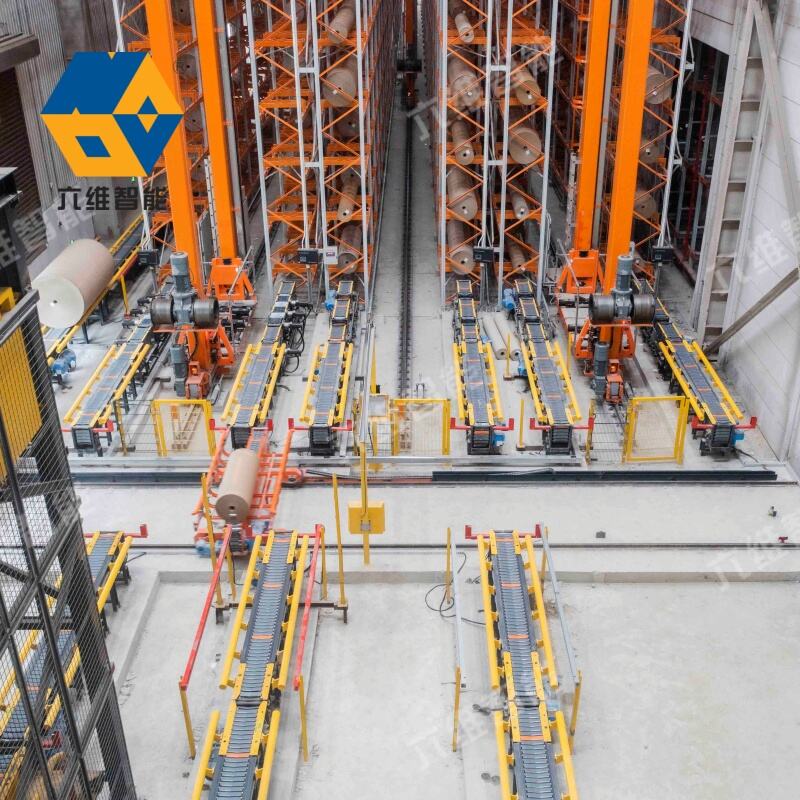

Warehouse shelving systems represent a fundamental component of modern storage and logistics operations, offering sophisticated solutions for organizing and maximizing storage space. These systems combine structural integrity with modular design principles to create versatile storage solutions that can adapt to various warehouse environments. The systems typically feature adjustable shelf levels, multiple configuration options, and weight-bearing capacities suited to different storage needs. Advanced warehouse shelving systems incorporate innovative materials such as high-grade steel and specialized coating technologies that enhance durability and resistance to wear. They often include safety features like load indicators, anti-collapse mechanisms, and seismic protection elements. These systems can be integrated with modern warehouse management technologies, including barcode scanning systems, RFID tracking, and automated inventory management solutions. The applications range from small business storage to large-scale distribution centers, accommodating various items from lightweight consumer goods to heavy industrial equipment. The systems can be customized with accessories such as dividers, bins, and specialized attachments to optimize storage efficiency and organization.