industrial shelving systems

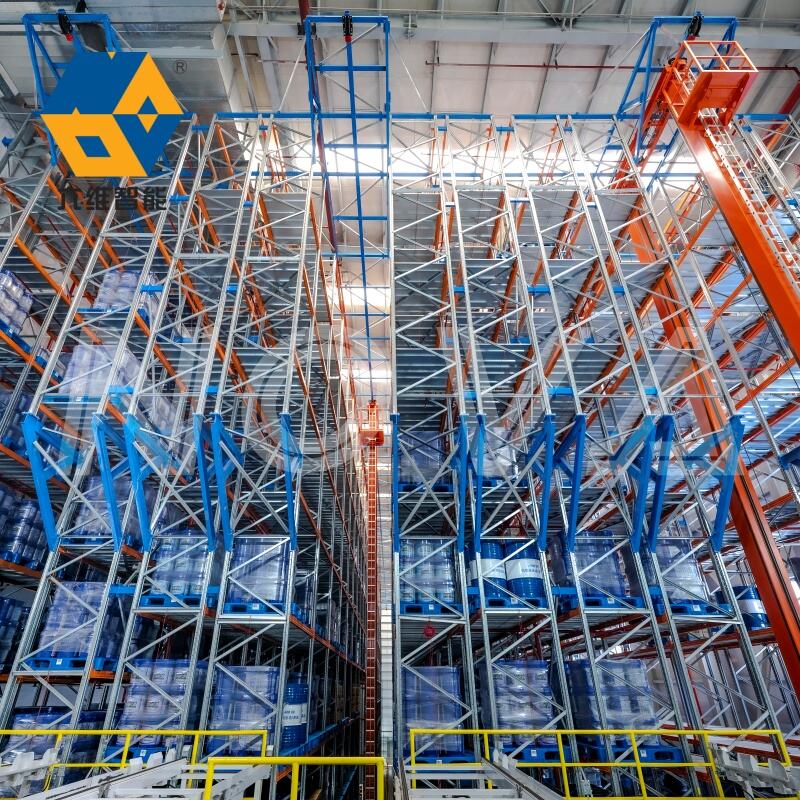

Industrial shelving systems represent a cornerstone of modern warehouse and storage management, offering robust solutions for organizing and storing various materials efficiently. These systems combine durability with flexibility, featuring adjustable components that can be customized to accommodate different load capacities and item sizes. Typically constructed from high-grade steel or similar robust materials, these shelving units are engineered to withstand heavy loads while maintaining structural integrity over extended periods. The systems often incorporate advanced safety features such as cross-bracing and locking mechanisms, ensuring stability even in high-traffic industrial environments. Modern industrial shelving systems come equipped with modular designs that allow for easy expansion or reconfiguration as storage needs evolve. They can be integrated with various material handling equipment and warehouse management systems, featuring compatibility with forklifts, pallet jacks, and automated retrieval systems. The versatility of these systems extends to their application across multiple industries, from manufacturing and retail to healthcare and logistics. Many models include specialized features such as wire decking, waterfall steps, and protective guards, enhancing both functionality and safety. These systems can be configured in single or multi-tier arrangements, maximizing vertical space utilization while maintaining accessibility to stored items.