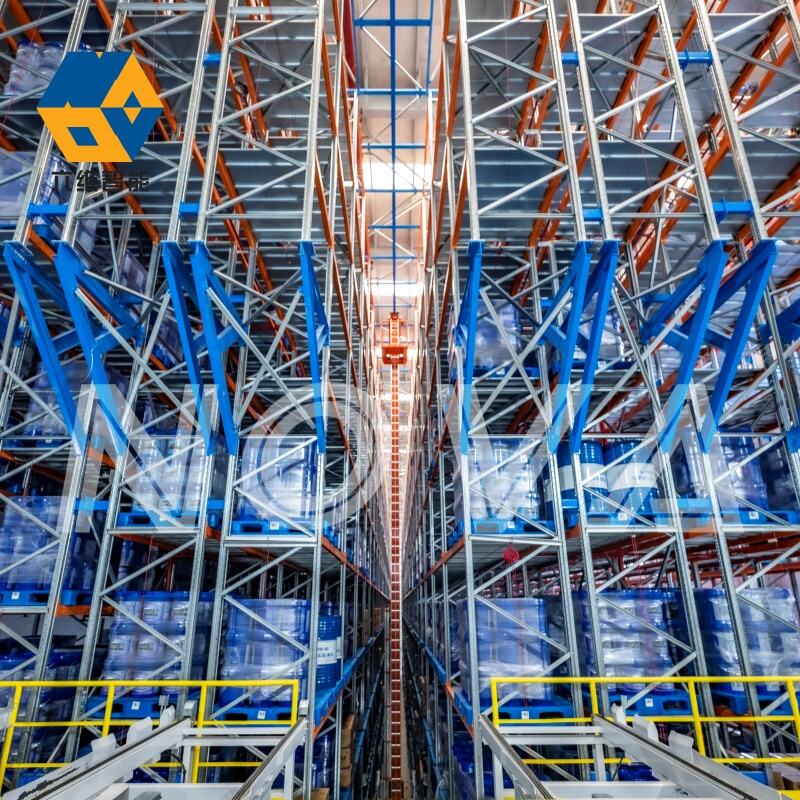

asrs warehouse

An Automated Storage and Retrieval System (ASRS) warehouse represents a cutting-edge solution in modern logistics and warehouse management. This sophisticated system combines advanced robotics, computer control systems, and inventory tracking software to create a highly efficient storage environment. The primary function of an ASRS warehouse is to automatically place and retrieve loads from defined storage locations, significantly reducing manual intervention in warehouse operations. The system utilizes various components including storage racks, automated cranes, conveyor systems, and pickup and delivery stations, all orchestrated by a warehouse management system. Through precision control and real-time inventory tracking, ASRS can manage multiple storage lanes simultaneously, handling both palletized and non-palletized goods with remarkable accuracy. The technology incorporates sensors and scanning systems to ensure precise product placement and retrieval, while maintaining detailed records of all warehouse movements. These systems can operate in various environments, including cold storage facilities, and can be scaled to accommodate different warehouse sizes and throughput requirements. The integration of ASRS with other warehouse management tools creates a comprehensive solution that optimizes space utilization, increases operational efficiency, and maintains inventory accuracy at levels previously unattainable with conventional warehouse systems.