unit load asrs

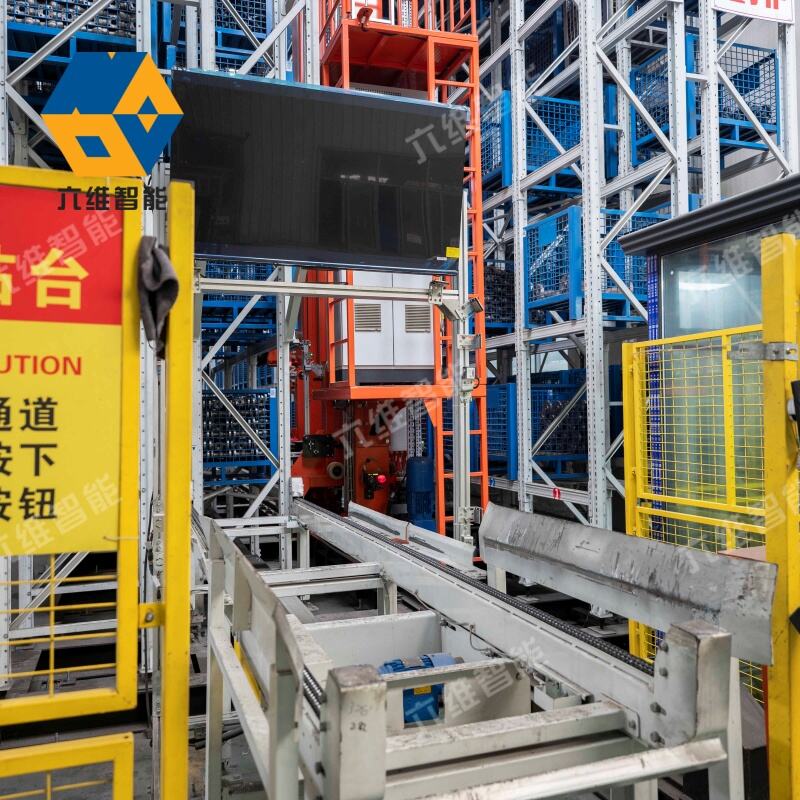

A Unit Load Automated Storage and Retrieval System (Unit Load ASRS) represents a cutting-edge warehousing solution that efficiently manages and handles large-scale storage operations. This sophisticated system combines advanced robotics, computer control systems, and specialized storage structures to automatically store and retrieve palletized loads. The system typically consists of storage racks, automated cranes that operate in aisles between racks, input/output stations, and a comprehensive warehouse management system. Unit Load ASRS can handle items stored on pallets, in containers, or other standardized load carriers, with typical load capacities ranging from 1,000 to 5,000 pounds. The system operates through a network of rails, allowing automated cranes to move both horizontally and vertically to access any storage location within the facility. Modern Unit Load ASRS implementations feature advanced sensors and positioning systems that ensure precise load placement and retrieval, while integrated inventory management software provides real-time tracking and optimization of storage space. These systems are particularly valuable in facilities with high-volume storage requirements, limited floor space, or the need for accurate inventory control.