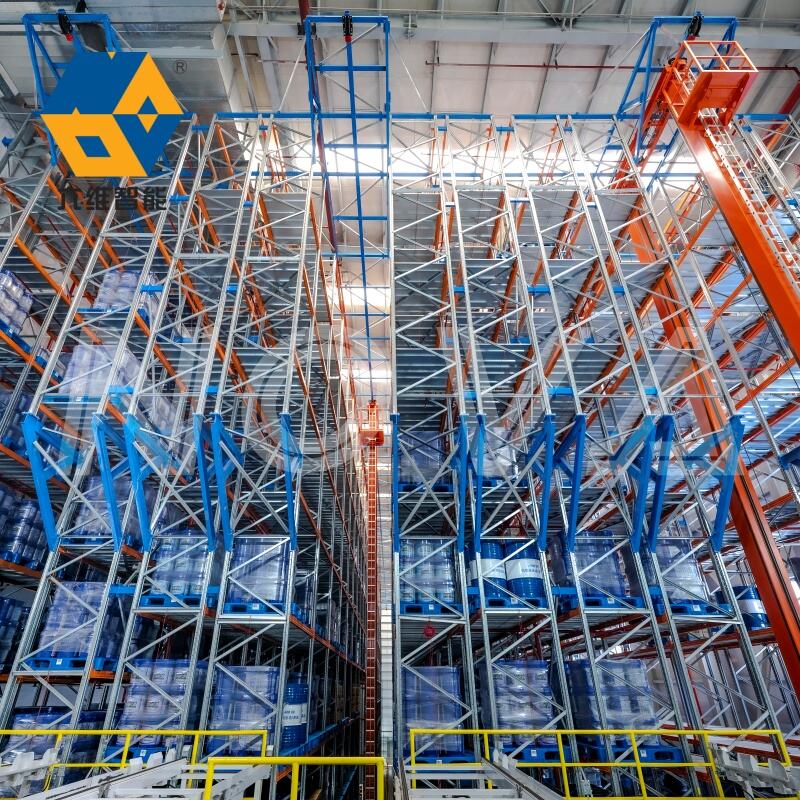

automated storage and retrieval

Automated Storage and Retrieval Systems (AS/RS) represent a cutting-edge solution in modern warehouse management, combining advanced robotics, computer control, and storage technology. These systems utilize a network of automated mechanisms, including cranes, shuttles, and conveyors, operating within a structured storage environment to handle, store, and retrieve products with minimal human intervention. The system operates through sophisticated software that coordinates all movements, tracking inventory locations and managing retrieval sequences in real-time. At its core, AS/RS employs vertical storage columns with multiple levels, maximizing warehouse space utilization by building upward rather than outward. The technology incorporates precision sensors and positioning systems to ensure accurate product placement and retrieval, while integrated inventory management software provides continuous tracking and status updates. These systems can handle various load sizes and types, from small parts to full pallets, making them versatile for different industry applications. Common implementations include manufacturing facilities, distribution centers, cold storage warehouses, and retail fulfillment centers. The system's ability to operate 24/7 with consistent accuracy and speed has made it an essential tool in modern logistics operations.