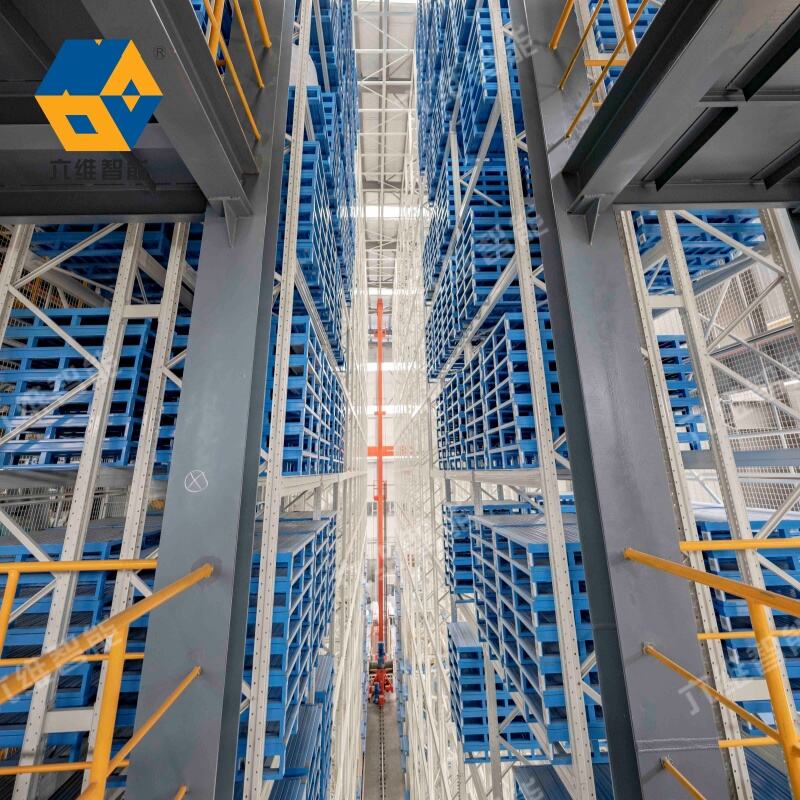

storage and retrieval system

A storage and retrieval system represents a sophisticated solution designed to optimize warehouse operations through automated handling and organization of materials. This advanced system combines mechanical components, digital control systems, and intelligent software to create a seamless workflow for inventory management. The system utilizes vertical lift modules, automated guided vehicles (AGVs), and robotic picking mechanisms to efficiently store and retrieve items within a warehouse setting. Its primary functions include automated storage allocation, rapid item retrieval, inventory tracking, and space optimization. The system employs advanced algorithms to determine optimal storage locations based on factors such as item size, weight, frequency of access, and available space. Real-time monitoring capabilities enable precise tracking of inventory movements, while integrated sensors and safety systems ensure secure operations. The technology can be applied across various industries, including manufacturing, retail distribution, pharmaceutical storage, and automotive parts management. The system's modular design allows for customization based on specific facility requirements and can be scaled to accommodate growing business needs. Integration capabilities with existing warehouse management systems (WMS) and enterprise resource planning (ERP) software enhance overall operational efficiency.