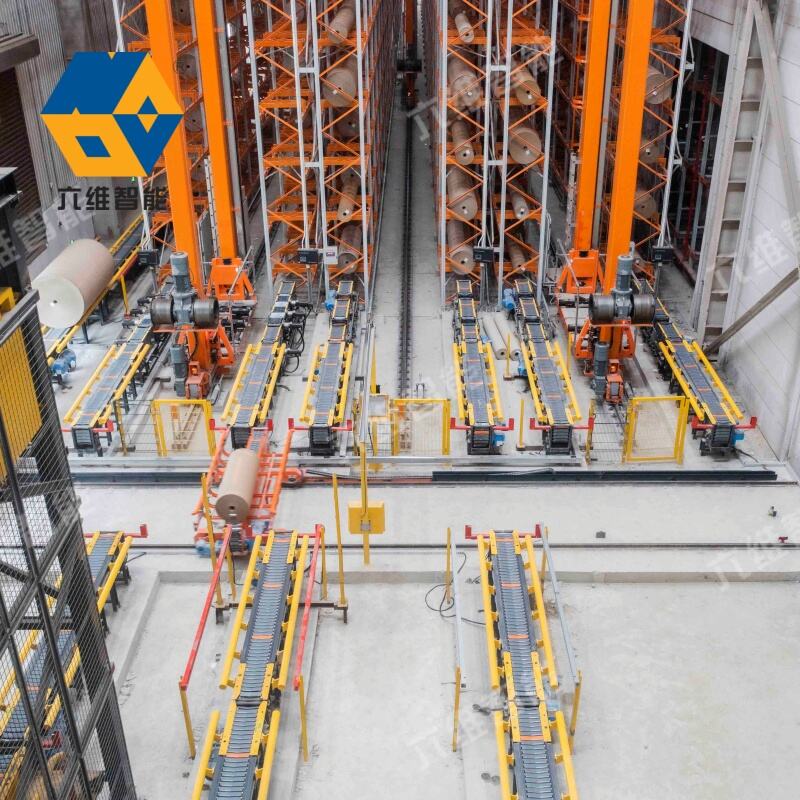

industrial warehouse shelving

Industrial warehouse shelving represents a cornerstone of modern storage solutions, offering businesses a systematic approach to maximize space utilization and streamline operations. These robust storage systems are engineered with precision using high grade steel and advanced manufacturing techniques, ensuring durability and reliability under heavy load conditions. The shelving systems come in various configurations, including selective pallet racking, drive in racking, and cantilever systems, each designed to accommodate different storage needs. Modern industrial warehouse shelving incorporates smart features like adjustable beam levels, wire decking, and safety locks, allowing for customizable storage solutions that can adapt to changing inventory requirements. These systems can typically support weights ranging from 2,000 to 5,000 pounds per level, depending on the configuration and materials used. The versatility of these storage solutions extends beyond traditional warehousing, finding applications in retail backrooms, manufacturing facilities, distribution centers, and cold storage environments. The implementation of these shelving systems often integrates with warehouse management software, enabling efficient inventory tracking and optimized space utilization. Advanced coating technologies provide protection against corrosion and wear, extending the operational lifespan of the shelving units while minimizing maintenance requirements.