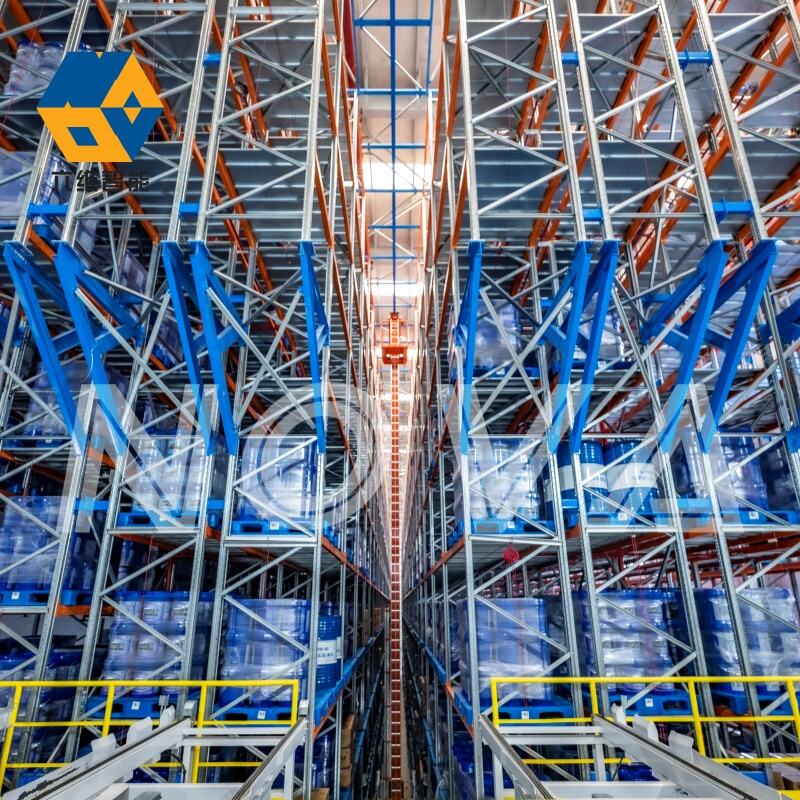

asrs systems

Automated Storage and Retrieval Systems (ASRS) represent a cutting-edge solution in modern warehouse management, combining advanced robotics, computer control, and inventory tracking technology. These systems utilize automated methods to store and retrieve products from defined storage locations, maximizing vertical space usage and minimizing manual intervention. ASRS systems typically consist of multiple components including storage racks, retrieval machines, conveyors, and a sophisticated warehouse management system. The technology operates through computerized controls that direct automated cranes and shuttles to navigate through storage aisles, picking and placing items with precision. These systems can handle various load sizes, from small parts to full pallets, and operate 24/7 with consistent accuracy. The implementation of ASRS significantly reduces the need for manual labor while increasing storage density by up to 85% compared to traditional warehousing methods. The system's ability to integrate with existing warehouse management software ensures real-time inventory tracking and seamless order fulfillment. Additionally, ASRS systems incorporate advanced safety features and redundancy measures to maintain operational reliability and protect both products and personnel.