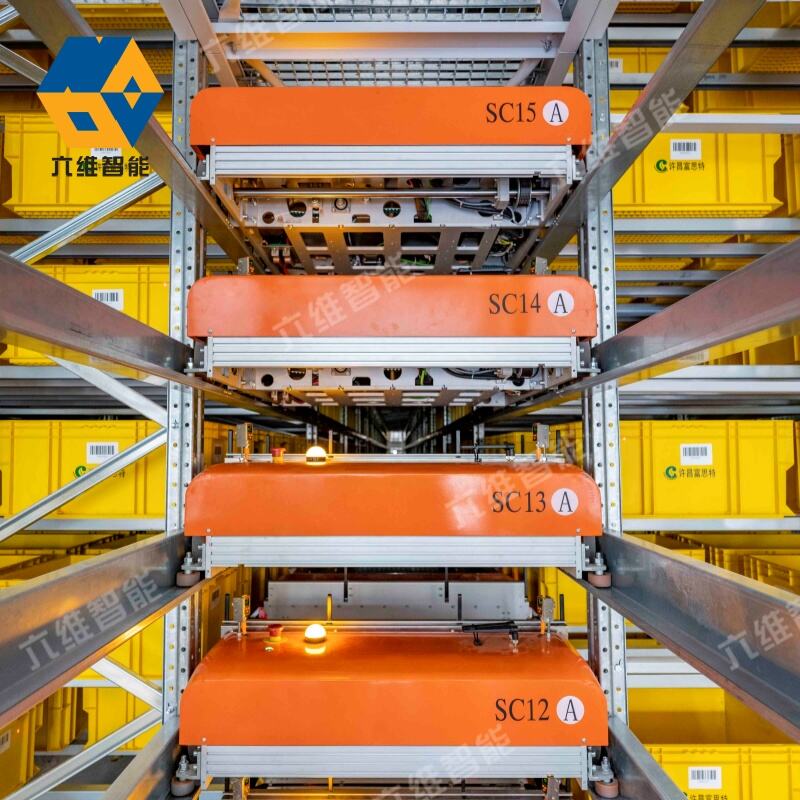

drive through racking system

Drive through racking systems represent a revolutionary approach to warehouse storage solutions, offering a highly efficient method for managing high-density storage needs. This innovative system consists of continuous lanes of racking that allow forklifts to drive directly into the storage structure, facilitating both loading and unloading operations from either end. The system is designed with specialized support rails that run the entire length of the storage lane, enabling pallets to be stored several positions deep. One of the key technological features is the robust guide rail system that ensures precise forklift alignment, minimizing the risk of damage to both products and infrastructure. The racking structure is engineered to handle substantial weight loads while maintaining structural integrity, incorporating heavy duty components and reinforced support beams. In practical applications, drive through racking systems excel in environments where storage density is paramount, particularly in cold storage facilities, food and beverage warehouses, and manufacturing sectors where large quantities of similar products need to be stored. The system's design allows for optimal space utilization, often achieving up to 75% more storage capacity compared to traditional racking solutions. Modern drive through systems also incorporate advanced safety features, including impact protection guards, load indicators, and specially designed entry and exit profiles to facilitate smooth operation.