pallet rack supply

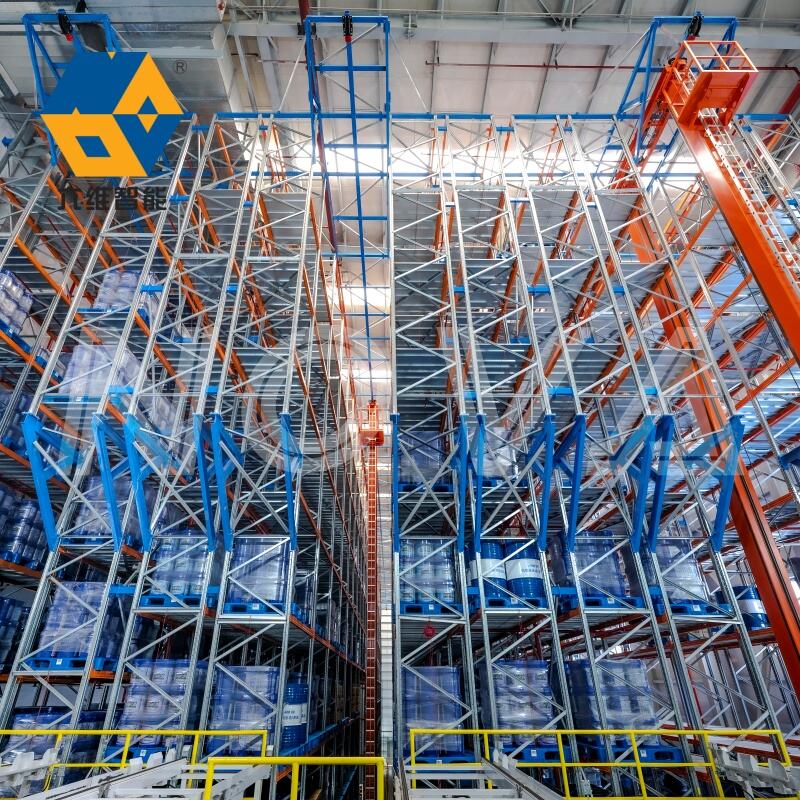

Pallet rack supply systems represent a cornerstone of modern warehousing and logistics operations, offering an efficient and organized solution for material storage and handling. These systems comprise vertical frames and horizontal beams designed to accommodate standardized pallets, enabling businesses to maximize vertical space utilization while maintaining easy access to inventory. The technological features include adjustable beam levels, heavy-duty steel construction, and various safety components such as frame protectors and wire mesh decking. Modern pallet rack systems incorporate advanced load-bearing calculations and precise engineering to ensure optimal weight distribution and structural integrity. These systems can be customized with different configurations, including selective, drive-in, push-back, and flow rack designs, each serving specific operational requirements. The applications span across various industries, from retail distribution centers to manufacturing facilities, cold storage warehouses, and e-commerce fulfillment centers. The systems can be integrated with automated storage and retrieval systems (AS/RS), warehouse management software, and other technological solutions to enhance operational efficiency.