asrs

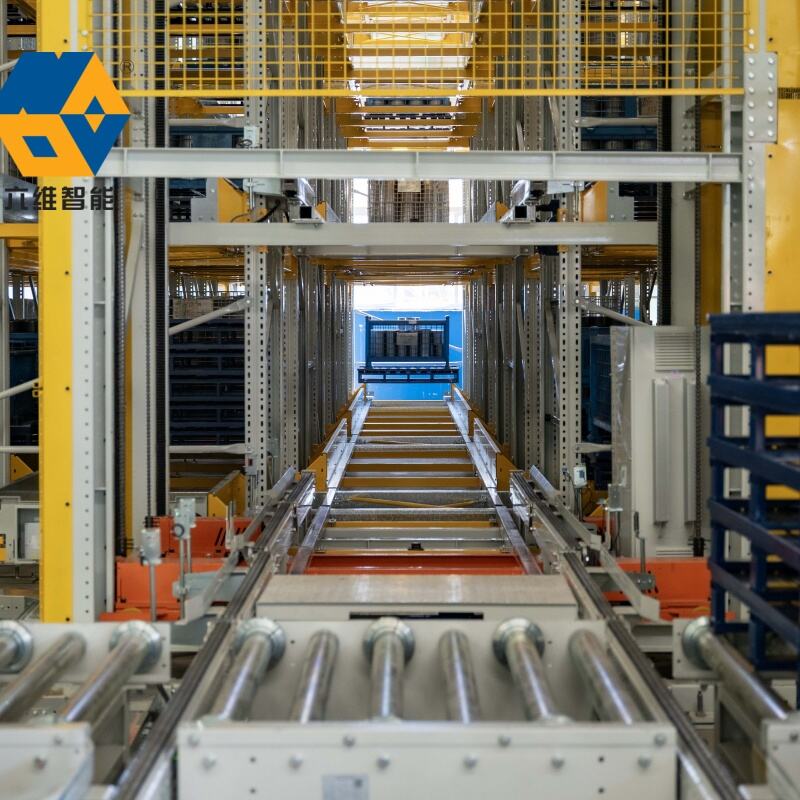

Automated Storage and Retrieval Systems (ASRS) represent a cutting-edge solution in modern warehousing and logistics operations. These sophisticated systems combine computer-controlled automation with precise mechanical systems to efficiently store and retrieve products within a warehouse setting. At their core, ASRS utilize robotic shuttles, cranes, and conveyors working in harmony to manage inventory in high-density storage areas. The system operates through a complex network of software and hardware components, including warehouse management systems (WMS), automated guidance systems, and sensor technologies. ASRS can handle various load types, from small parts to full pallets, and operate in both ambient and temperature-controlled environments. The technology employs vertical lift modules, horizontal carousels, and unit-load systems to maximize storage density while minimizing floor space requirements. Modern ASRS implementations feature advanced safety protocols, real-time inventory tracking, and predictive maintenance capabilities. These systems can operate 24/7, significantly reducing human error and labor costs while increasing throughput and accuracy rates to nearly 99.9%. The versatility of ASRS makes them suitable for various industries, including manufacturing, retail distribution, pharmaceutical storage, and e-commerce fulfillment centers.