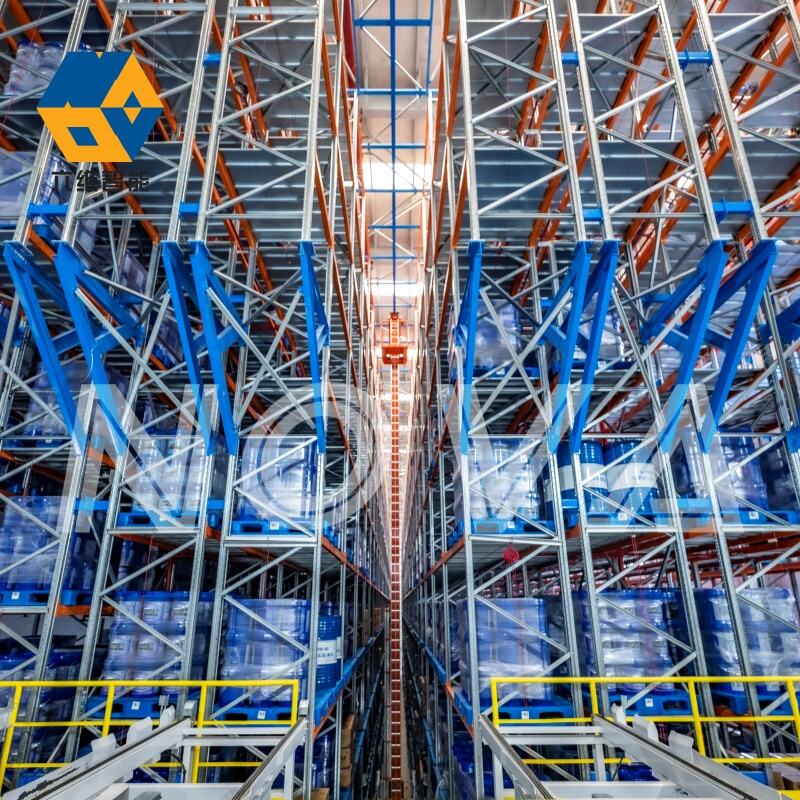

fifo racking

FIFO (First-In-First-Out) racking represents a sophisticated storage solution designed to optimize warehouse operations and inventory management. This advanced system ensures that the first products stored are the first ones retrieved, making it particularly valuable for managing perishable goods and maintaining strict inventory rotation. The system typically consists of inclined shelves with rollers or wheels, allowing products to automatically move forward when items are retrieved from the picking face. Each lane is carefully engineered with a specific slope, typically between 3 to 5 degrees, enabling gravity to facilitate product movement while maintaining controlled flow rates. Modern FIFO racking systems incorporate advanced safety features, including speed controllers and separators, to prevent product damage during movement. The structure can accommodate various load sizes and weights, with adjustable lane widths and depths to maximize storage density. These systems can be configured as single or double-deep arrangements, offering flexibility in warehouse layout design. The technology integrates seamlessly with automated warehouse management systems, enabling real-time inventory tracking and reducing manual handling requirements. FIFO racking finds extensive applications in industries such as food and beverage, pharmaceuticals, and automotive parts, where inventory rotation and date control are crucial.