vna racking

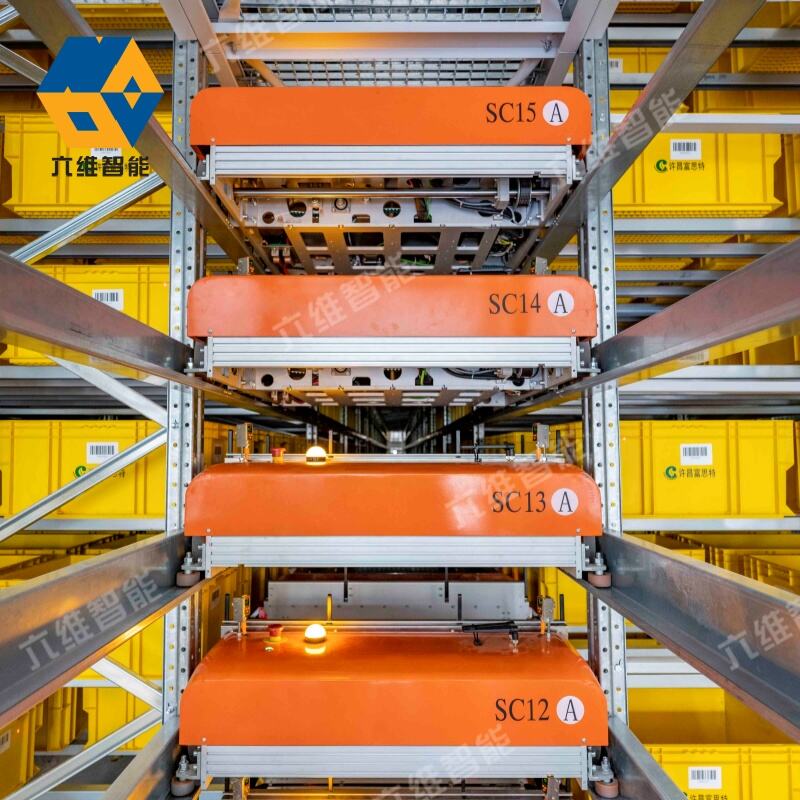

VNA (Very Narrow Aisle) racking represents a revolutionary storage solution designed to maximize warehouse space utilization through its innovative vertical storage capabilities. This advanced racking system enables businesses to create extremely narrow aisles, typically between 1.5 to 1.8 meters wide, allowing for significantly increased storage density compared to conventional racking systems. The system incorporates specialized guide rails and precision-engineered uprights that can reach heights of up to 15 meters, effectively utilizing vertical space while maintaining stability and safety. VNA racking systems are equipped with sophisticated wire guidance or rail guidance systems that work in conjunction with specialized VNA forklifts, ensuring accurate and safe navigation through the narrow aisles. The system's design incorporates advanced load-bearing components and high-grade steel construction, capable of handling various pallet weights and sizes. Modern VNA racking installations often feature integrated inventory management systems, including barcode scanning capabilities and real-time stock monitoring, enhancing operational efficiency and accuracy. This storage solution is particularly valuable in high-cost areas where maximizing storage capacity per square foot is crucial, making it an ideal choice for distribution centers, manufacturing facilities, and large-scale warehouses seeking to optimize their storage space.