miniload system

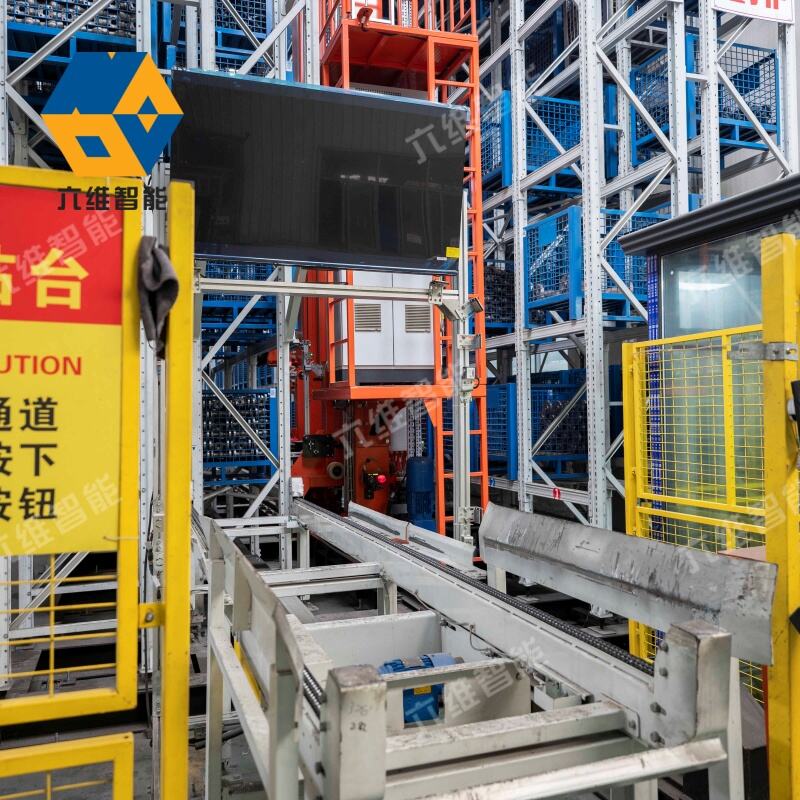

A miniload system represents a cutting-edge automated storage and retrieval solution designed for handling small to medium-sized items in warehouses and distribution centers. This sophisticated system combines high-speed robots, precision engineering, and intelligent software to create an efficient storage mechanism that maximizes vertical space utilization. The system operates through automated storage and retrieval machines that move along aisles between storage racks, capable of handling totes, cartons, and containers weighing up to 50kg. At its core, the miniload system employs a combination of advanced sensors, positioning systems, and control software to ensure accurate and rapid handling of goods. The technology enables quick access to stored items through a goods-to-person principle, where products are automatically retrieved and delivered to ergonomic picking stations. Modern miniload systems integrate seamlessly with warehouse management systems (WMS) and can process hundreds of storage and retrieval operations per hour. These systems find extensive applications in various industries, including e-commerce fulfillment centers, pharmaceutical distribution, automotive parts storage, and retail logistics operations, providing an ideal solution for businesses seeking to optimize their storage capabilities while maintaining high throughput rates.