industrial mezzanine floor

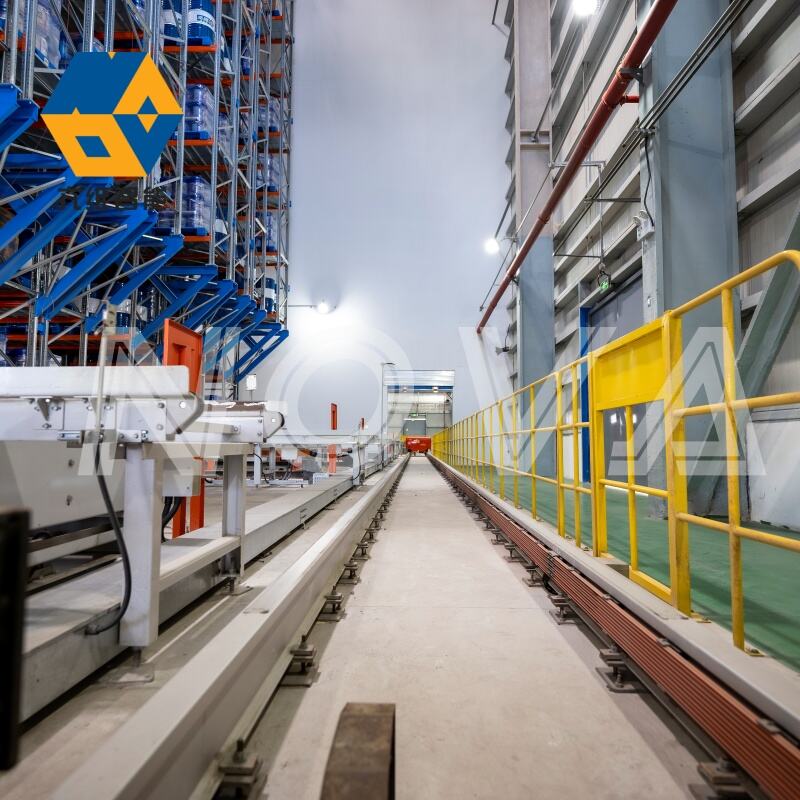

Industrial mezzanine floors represent a revolutionary solution in maximizing warehouse and manufacturing space utilization. These elevated platforms are engineered structures that create additional usable floor space without the need for facility expansion. Constructed from high-grade steel and other durable materials, these installations can be customized to meet specific load-bearing requirements and spatial configurations. The design incorporates strategic support columns, robust decking systems, and safety features such as handrails and access stairs. Modern industrial mezzanine floors often feature integrated lighting systems, fire protection measures, and various flooring options including steel grating, solid panels, or composite materials. These structures can be utilized for multiple purposes, from storage and inventory management to creating office spaces or production areas. The versatility of industrial mezzanine floors extends to their installation process, which can be completed with minimal disruption to existing operations. They can be designed as free-standing structures or integrated into the building's framework, offering flexibility in both permanent and temporary applications. The engineering behind these systems ensures optimal weight distribution and structural integrity while maintaining compliance with building codes and safety regulations.