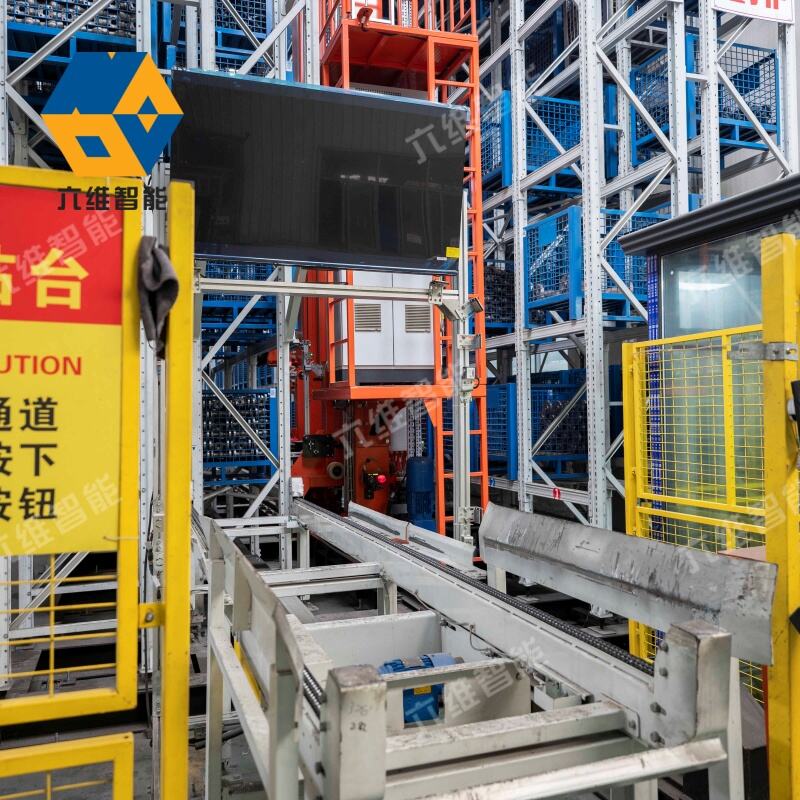

storage retrieval system

A storage retrieval system represents a sophisticated solution for managing and organizing inventory through automated mechanisms. This advanced system combines mechanical components, software controls, and intelligent algorithms to efficiently store, track, and retrieve items within a warehouse or distribution center. At its core, the system utilizes automated storage and retrieval machines (AS/RS) that operate along aisles between storage racks, capable of handling various load sizes and types. The system employs precision positioning technology to ensure accurate placement and retrieval of items, while integrated sensors and cameras monitor operations in real-time. Modern storage retrieval systems feature advanced inventory management software that maintains detailed records of item locations, movement history, and stock levels. The technology incorporates multiple safety features, including collision prevention systems and emergency protocols, ensuring secure operation. These systems can be customized to accommodate different storage requirements, from small parts to large pallets, and can operate in various environments, including cold storage facilities. The integration capabilities allow seamless connection with existing warehouse management systems (WMS) and enterprise resource planning (ERP) software, enabling comprehensive supply chain visibility and control.